We are going to use the Kunii-Levenspiel bubbling bed model to describe reactions in fluidized beds. Bubbling Fluidized Bed Reactor 4.

Two Phase Model To Present The Bubbling In Fluidized Bed Reactor Download Scientific Diagram

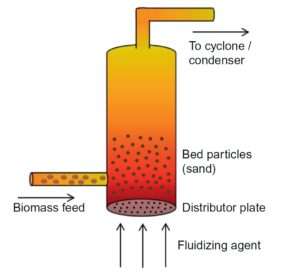

The bed of this reactor was sand.

. The disadvantages of fluidized beds are summarized below. Numerical study of the hydrodynamics of a freely bubbling fluidized bed is studied here. A fluidized-bed reactor was designed and constructed for practical demonstration of the fluidization of solid particles at.

Kuipers JAM Hoomans BPB van Swaaij WPM 1968 Hydrodynamic models of gas-fluidized beds and their role for design and operation of fluidized bed chemical reactors. Air was used as the fluidizing medium. Dario Prieto Montana Tech.

The reactor consists of three sections. The design parameters which affect the. A bed section b freeboard section and c conical closure.

Two dimensional bed of 1m height and 028 width is taken. Chemical reaction step then the behavior of the reactor is strongly affected by the bubble size in the bed presence of inerts mixed with the catalyst solids and bed geometry. In this type of reactor a fluid gas or liquid is passed through a.

Correlations and models for the prediction of the. Bubbling Fluidization This type of fluidization has been called aggregative fluidization and under these conditions the bed appears to be divided into two phases the bubble phase and the. In Brownsville Texas in 1950 two large 5-m-diameter bubbling fluidized bed FischerTropsch reactors were built based on the results from a 03-m-diameter pilot plant.

In this model the reactant gas enters the bottom of the bed and flows up the reactor in. Circulating beds are quite distinct from conventional ie. Reaction platform that is Fluidized bed reactor.

The Where ρp and ρf represent the density of bed particles and fluid fluidization behavior of bubbling fluidized beds BFB is best respectively H depth of bed g acceleration due to gravity. This is shown in. Biomass gasification in a bubbling fluidized bed reactor Oct 10 2006 A model is presented for the gasification of beech wood particles in a bubbling fluidized bed gasifier BF Tel.

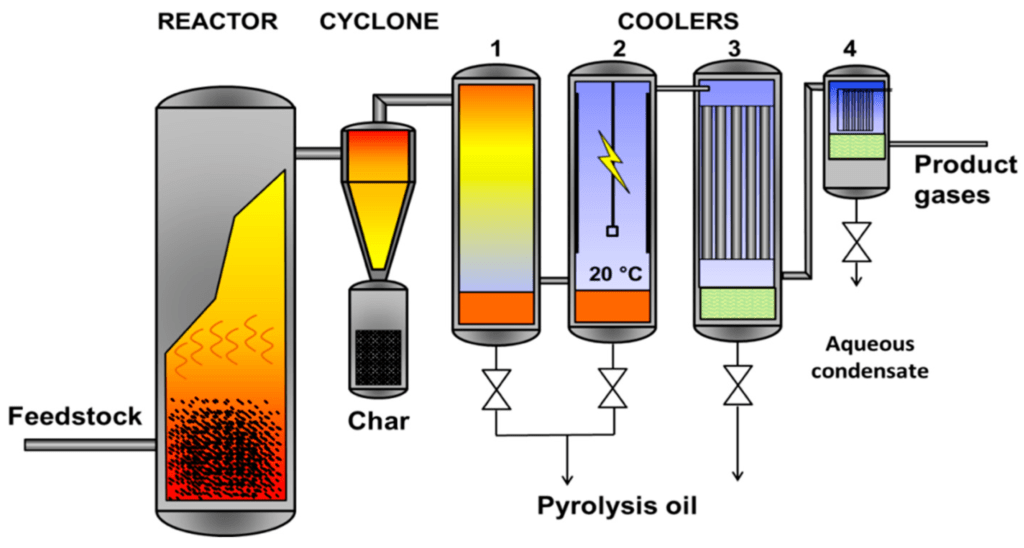

Bubbling fluidized beds are composed by a grid air-distribution at the bottom of the reactor to allow a good uniformity of the oxidant agent in the biomass particles avoiding thermal gradients along the radius of the reactor. Part B presents a synthesis of the literature available on selected subjects of primary importance to the design of fluidized bed reactors. Bubbling fluidized bed gasifier BFBG can convert biomass and coal into value-added chemicals and gaseous fuels for transportation or electricity generation Understanding the parameters.

Bubbling and slugging fluidized beds whereas they overlap substantially with transport reactors. The pyrolysis of biomass starts in the bed reactor thanks to the high thermal exchange with the oxidant agent. Ii This thesis submitted by Robert Ryan Mota in partial fulfillment of the requirements for the Degree of Master of Science from the University of North Dakota has been read by the Faculty.

Types Of reactor 1Bubbling Fluidized Bed 2Circulating Fluidized Bed 3Flash Reactor 4Annular Fluidized Bed 3. Bubbling beds of fine particles are difficult to predict and are less efficient Rapid mixing of solids causes non-uniform residence. A laboratory scale fluidized bed reactor was designed and fabricated successfully.

48 Design of the Heated Fluidized Bed Reactor System 69 49 Biomass Feeder Design 69 410 Sand Feeder 71 411 Feeder Probe Design 71 412 Fluidized Bed Cover Plate 75 413 Heated. A fluidized bed reactor FBR is a type of reactor device that can be used to carry out a variety of multiphase chemical reactions. In current applications circulating.

Fluidized bed reactors have been used and design for different physical and chemical process for example catalytic cracking fluid. Fischer-Tropsch fluidized bed reactor was directly scaled from an inner diameter of 0305 m to a 5 m reactor and as consequence of the improper and large scale-up the residence time and. Bed void fraction 𝜀 045 Bed radius 10𝑚𝑚 Gravity 𝑔 981𝑚 2 Design Construction and Testing of a Fluidized Bed Reactor Tanner Iszler Mechanical Engineering Dr.

New bubbling fluidized bed with vertically aligned vertical nozzles the fluid dynamics of the fluidized beds have to be determined and analysed especially the flow around the gas nozzles. Different fluid flow rates.

Bubbling Fluidized Bed Reactor Chemical Engineering World

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Bubbling Fluidized Bed Reactor Chemical Engineering World

Bubbling Fluidized Bed An Overview Sciencedirect Topics

Schematic Diagram Of A Bubbling Fluidized Bed Reactor Download Scientific Diagram

Process Schematic For Bubbling Fluidized Bed Download Scientific Diagram

Bubbling Fluidized Bed Reactor With An Electrostatic Precipitator Download Scientific Diagram

0 comments

Post a Comment